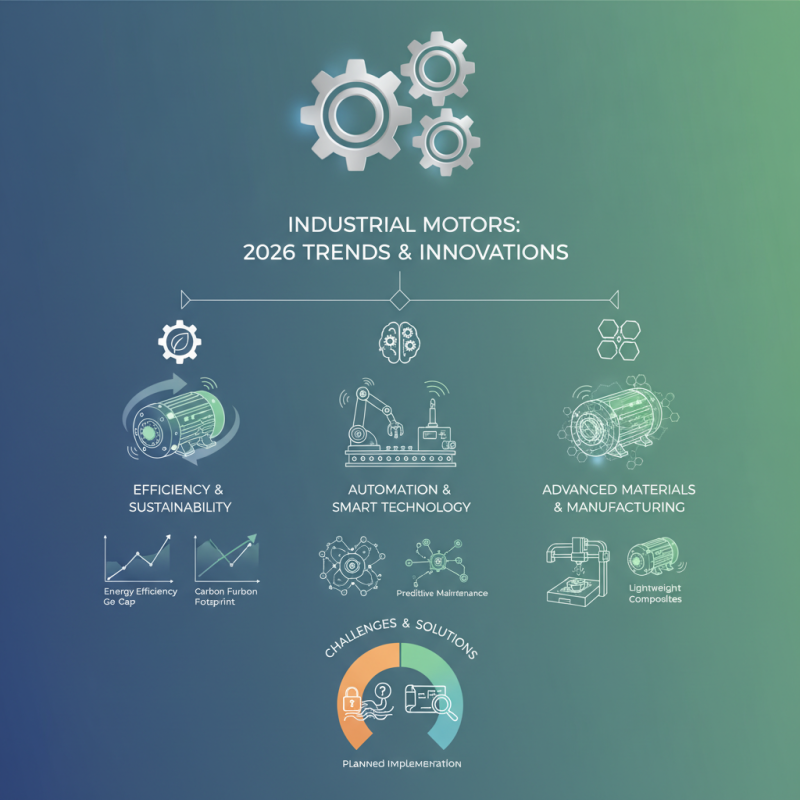

2026 Top Industrial Motors Trends and Innovations in Technology?

In the evolving landscape of industrial motors, innovation is key. Dr. Emily Smith, a renowned expert in motor technology, states, “The future of industrial motors will shape efficiency and sustainability.” As industries focus on reducing their carbon footprint, advancements in motor design are crucial.

The demand for high-performance and energy-efficient industrial motors is increasing. In 2026, we expect significant trends driven by automation and smart technology. Companies are exploring lightweight materials and advanced manufacturing processes. These changes will impact both performance and maintenance.

However, challenges remain. Many manufacturers struggle with integrating new technologies into existing systems. The gap between innovation and practical application needs attention. The rush to adopt the latest technology can lead to shortcomings. Effective solutions require careful planning and consideration of real-world applications in industrial motors.

2026 Industrial Motors Market Overview and Projections

The industrial motors market is evolving rapidly. Projections for 2026 show significant growth driven by advancements in technology. Smart motors are gaining attention. These devices can monitor performance in real-time. They reduce energy consumption and improve efficiency.

Market research suggests a shift towards electricity-driven motors. The demand for environmentally friendly solutions is rising. Energy-efficient motors can cut costs and reduce carbon footprints. However, the integration of these technologies poses challenges. Manufacturers may struggle to adapt to the new standards. Training staff to handle these innovations can also be an issue.

Moreover, the competitive landscape is changing. Suppliers must keep up with market demands. Some companies may lag behind due to outdated practices. This gap in innovation can hinder their growth. Embracing new trends will be essential for success. The future of industrial motors relies on adaptability and foresight.

2026 Top Industrial Motors Trends and Innovations in Technology

| Trend/Innovation | Description | Projected Adoption Rate (%) | Impact on Efficiency (%) | Market Segment |

|---|---|---|---|---|

| IoT Integration | Enhanced connectivity in industrial motors allowing real-time monitoring and analytics. | 75 | 20 | Manufacturing |

| Energy Efficiency Standards | Adoption of strict energy consumption regulations for motors. | 80 | 30 | Energy |

| Sustainable Materials | Use of recyclable materials in motor construction. | 60 | 15 | OEM |

| Advanced Control Systems | Implementation of AI-based controls for enhanced performance. | 70 | 25 | Automation |

| Digital Twin Technology | Creation of digital replicas of motors for simulation and analysis. | 65 | 22 | Construction |

Emerging Technologies Shaping Industrial Motors in 2026

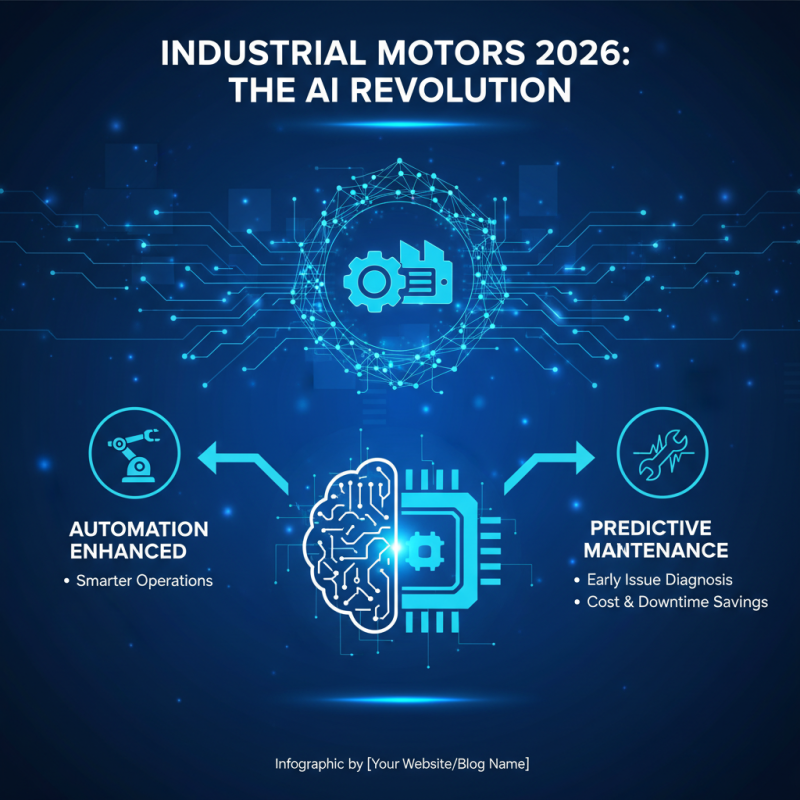

Emerging technologies are rapidly shaping the future of industrial motors in 2026. One significant trend is the integration of artificial intelligence. AI enhances automation and predictive maintenance. It helps in diagnosing issues before they escalate, potentially saving costs and downtime.

Another innovation is the shift towards energy-efficient designs. Improved materials and advanced manufacturing techniques are enabling motors that consume less power. These innovations are crucial as industries seek to lower their carbon footprints. However, challenges remain, such as the initial costs of new technology.

Additionally, the rise of IoT-enabled motors is noteworthy. These motors offer connectivity and real-time data analytics. This allows for better monitoring and optimization of performance. Nonetheless, ensuring security and data integrity is a concern that needs addressing. The balance between efficiency and safety must be carefully managed as these technologies evolve.

Key Trends in Energy Efficiency for Industrial Motors

Energy efficiency is a critical factor for industrial motors in the coming years. As industries strive to reduce operational costs and environmental impacts, energy-efficient technologies are gaining traction. High-efficiency motors can significantly lower energy consumption. Many companies are exploring improved designs and materials to achieve this.

Variable frequency drives (VFDs) are becoming popular. They help optimize motor performance by adjusting speed and torque as needed. However, implementing these solutions requires careful considerations. Not all systems can integrate seamlessly. Some facilities may face challenges in retrofitting existing equipment.

Another trend is the use of advanced sensors. Smart sensors can monitor energy use in real-time. They provide insights for enhanced performance. This helps identify inefficiencies but not every plant is ready for such upgrades. Costs and technical expertise can be significant barriers. Therefore, while the push for energy efficiency is strong, companies need to weigh potential benefits against real-world limitations.

The Role of IoT in Modern Industrial Motor Systems

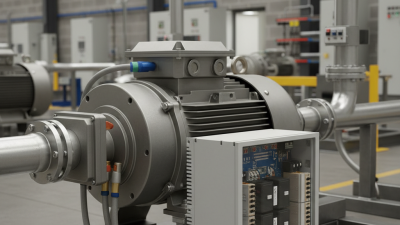

The Internet of Things (IoT) significantly transforms modern industrial motor systems. By connecting devices, IoT enhances efficiency and provides insights. Imagine motors that communicate with each other and share data in real time. This connection enables predictive maintenance. It helps prevent unexpected downtime, reducing costs.

However, the implementation of IoT is not without challenges. Security concerns arise as more devices connect. Vulnerability to cyberattacks can compromise systems. Moreover, data overload can lead to confusion. Workers might struggle with interpreting vast amounts of information. Training becomes essential to address these issues and maximize benefits.

As industries adopt IoT, the need for integration grows. Not all devices can communicate seamlessly yet. Older systems may create compatibility problems. Continuous improvements are necessary to ensure reliable operations. Despite these hurdles, the potential of IoT in industrial motors is undeniable. It fosters innovation and drives efficiency forward, yet it also demands careful consideration of risks.

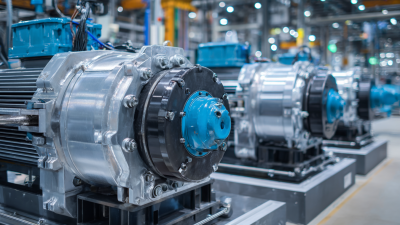

Innovations in Motor Design and Performance Enhancements

The industrial motor sector is experiencing significant innovations in design and performance enhancements. A recent report by Research and Markets indicated that the global industrial motors market will surpass $170 billion by 2026. This growth is driven by advancements in energy efficiency and smart technologies. Many manufacturers are now focusing on developing motors that offer improved performance while consuming less energy.

One notable trend is the rise of brushless motors. These motors provide greater efficiency and have a longer lifespan compared to traditional designs. The reduction in maintenance is a compelling advantage. However, there are still challenges surrounding their initial cost. Despite their long-term benefits, the upfront investment limits their adoption in some sectors.

Moreover, the integration of IoT technology in industrial motors is shaping future trends. Sensors and connectivity allow for real-time monitoring and predictive maintenance. This innovation can reduce downtime and operational costs. Yet, it raises questions about data security and the reliability of technology in critical applications. As the industry evolves, it must balance these advancements with practical considerations.

Related Posts

-

Understanding the Role of Industrial Electric Motors in Modern Automation Systems

-

Top 10 Industrial Motors: Key Features and Buying Guide for 2023

-

What are Electrical Breakers and Their Role in Electrical Safety Standards

-

The Ultimate Guide to Understanding 3 Phase Electric Motors: Efficiency, Applications, and Benefits

-

How to Choose the Right VFD Drive for Your Industrial Application

-

Why Do You Need a Soft Starter for Your Electrical Motor System?