How to Choose the Right Electric Motor VFD for Your Needs?

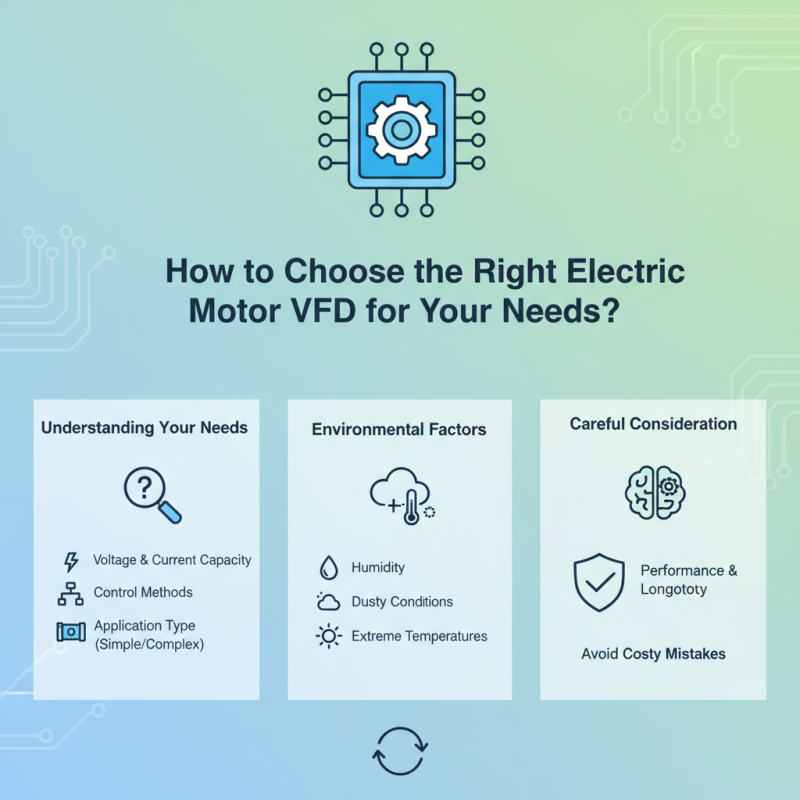

Choosing the right electric motor VFD can be a challenging task. The options are vast, and making a mistake can be costly. Understanding your specific needs is crucial.

Electric motor VFDs vary in features and specifications. Some are designed for simple applications, while others cater to complex demands. You need to consider factors such as voltage, current capacity, and control methods. Each detail matters.

Selecting a VFD requires careful thought. Consider the environment where the motor will operate. Is it humid, dusty, or exposed to extreme temperatures? Such conditions influence your choice. There might be limits on what can be used. Don't overlook these elements, as they can lead to performance issues.

Understanding the Basics of Electric Motors and VFDs

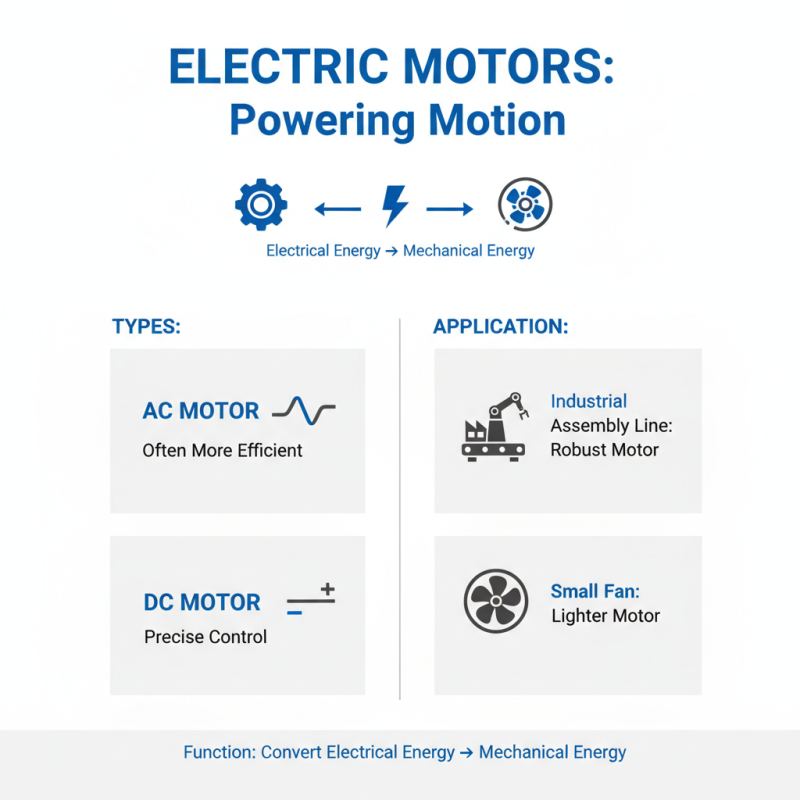

When selecting an electric motor, understanding its function is vital. Electric motors convert electrical energy into mechanical energy. They come in various types, such as AC and DC motors. AC motors are often more efficient, while DC motors offer precise control. Knowing the application is key. An industrial assembly line may require a robust motor, while a small fan needs something lighter.

Variable frequency drives (VFDs) enhance motor performance. They control the speed and torque of the motor, allowing for energy efficiency. They can also reduce wear and tear on the motor. However, choosing the right VFD is not always straightforward. Compatibility with the motor is critical. The wrong VFD can lead to errors or damage. You must consider factors like horsepower, voltage, and phase.

Sometimes, the complexity can feel overwhelming. Misjudging the specifications may lead to poor performance or even failure. Reflection is necessary. Evaluate your needs thoroughly before finalizing a choice. Don't rush this process. Making informed decisions now can save time and resources later.

Key Factors to Consider When Selecting a VFD

Selecting the right Variable Frequency Drive (VFD) for your electric motor can be complex. Different applications require different features. Understanding your specific needs is essential. For instance, consider motor type and load characteristics. This is crucial for ensuring a good match.

Next, evaluate the control method. Some VFDs use scalar control, while others offer advanced vector control. Vector control provides better performance but may be more complex. Think about your skill level with VFDs. If you are not experienced, simpler options might be better.

Another factor is the environment. Will the VFD operate in a dusty, wet, or hot area? Look for an enclosure rating that suits your situation. Lastly, think about budget constraints. Sometimes, less expensive options may lack necessary features. Reflect on how future-proof you need the system to be. This can help avoid costly replacements down the line.

Types of VFDs and Their Applications in Electric Motors

Choosing the right Variable Frequency Drive (VFD) is crucial for electric motor performance. Different types of VFDs serve various applications. For example, scalar VFDs are simple and cost-effective. They work well for basic motor control. However, they might not handle complex loads efficiently.

Vector control VFDs are more advanced. They provide precise speed control and torque regulation. This type is ideal for applications requiring high performance. Consider applications like conveyors, fans, or pumps. These systems often demand more from a VFD.

**Tips:** Assess your motor’s specifications carefully. Understand your load types and operation cycles. This can prevent oversizing or undersizing issues. Compatibility is key. Choose a VFD that can handle the environmental conditions of your application. Not all VFDs excel in extreme temperatures or humid conditions.

Remember, not every VFD is suited for every application. For critical operations, sometimes, failure in choosing the right VFD can lead to performance issues. Make decisions based on detailed research and technical advice. This helps in avoiding common pitfalls.

Assessing Load Requirements and Motor Characteristics

Choosing the right Variable Frequency Drive (VFD) starts with understanding your load requirements. Different applications demand varied performance levels. Assess whether your system requires high torque for start-up or smooth acceleration over time. This evaluation directly impacts the VFD selection. Load profiles may change, and miscalculating them could lead to inefficiencies or equipment failure.

Motor characteristics play a crucial role too. Know your motor’s rated power, voltage, and current ratings. Consider its speed-torque curve, which reveals how it performs under different conditions. A motor’s efficiency affects its compatibility with a VFD. If the motor isn't properly matched to the VFD specifications, problems could arise. Unforeseen situations, such as fluctuating loading conditions, need to be anticipated.

Take your time to review these parameters. Selecting a VFD without fully understanding these aspects can result in oversizing or undersizing. Revisit your choices and assess the implications on overall system performance. Each detail counts, and leaving them unchecked may lead to costly downtime or excessive energy consumption. Balancing these factors is key to a successful outcome.

Electric Motor VFD Selection: Load Requirements vs. Motor Characteristics

Installation and Maintenance Tips for Optimal VFD Performance

When it comes to electric motor VFD installation, many overlook the importance of proper setup. Ensure that the VFD is installed in a clean, dry environment. Dust and moisture can cause significant issues over time. Pay attention to the cooling requirements of the unit. An overheated VFD can lead to premature failure. Adjust ventilation as needed to keep the system running smoothly.

Maintenance is crucial for optimal VFD performance. Regularly inspect connections for corrosion or loose wiring. A simple visual check can prevent bigger problems later. Change the cooling fans or filters if they show signs of wear. This is often neglected but can be vital for the unit’s lifespan. Consider periodic inspections by a professional, even if it seems unnecessary. They might spot issues you missed.

Don’t ignore error codes or alarms from your VFD. They provide critical information about performance issues. Addressing these warnings promptly can save time and money. Keeping a maintenance log can aid in tracking performance trends. Reflect on your current processes. Are they effective? Adjust as needed to ensure your VFD operates at its best.

Related Posts

-

Understanding the Benefits of VFD Drive Technology in Modern Industries

-

Best VFD Drive for Energy Efficiency and Performance in Industrial Applications

-

Top Electric Motor VFD Types for Optimal Performance and Efficiency?

-

2025 Top 5 Electric Motors Revolutionizing Energy Efficiency and Performance

-

Why You Should Consider a Soft Start Motor Starter in 2026

-

How to Effectively Select the Right Motor Starter for Your Industrial Needs