7 Essential Tips for Optimizing Your Electric Motor VFD Efficiency

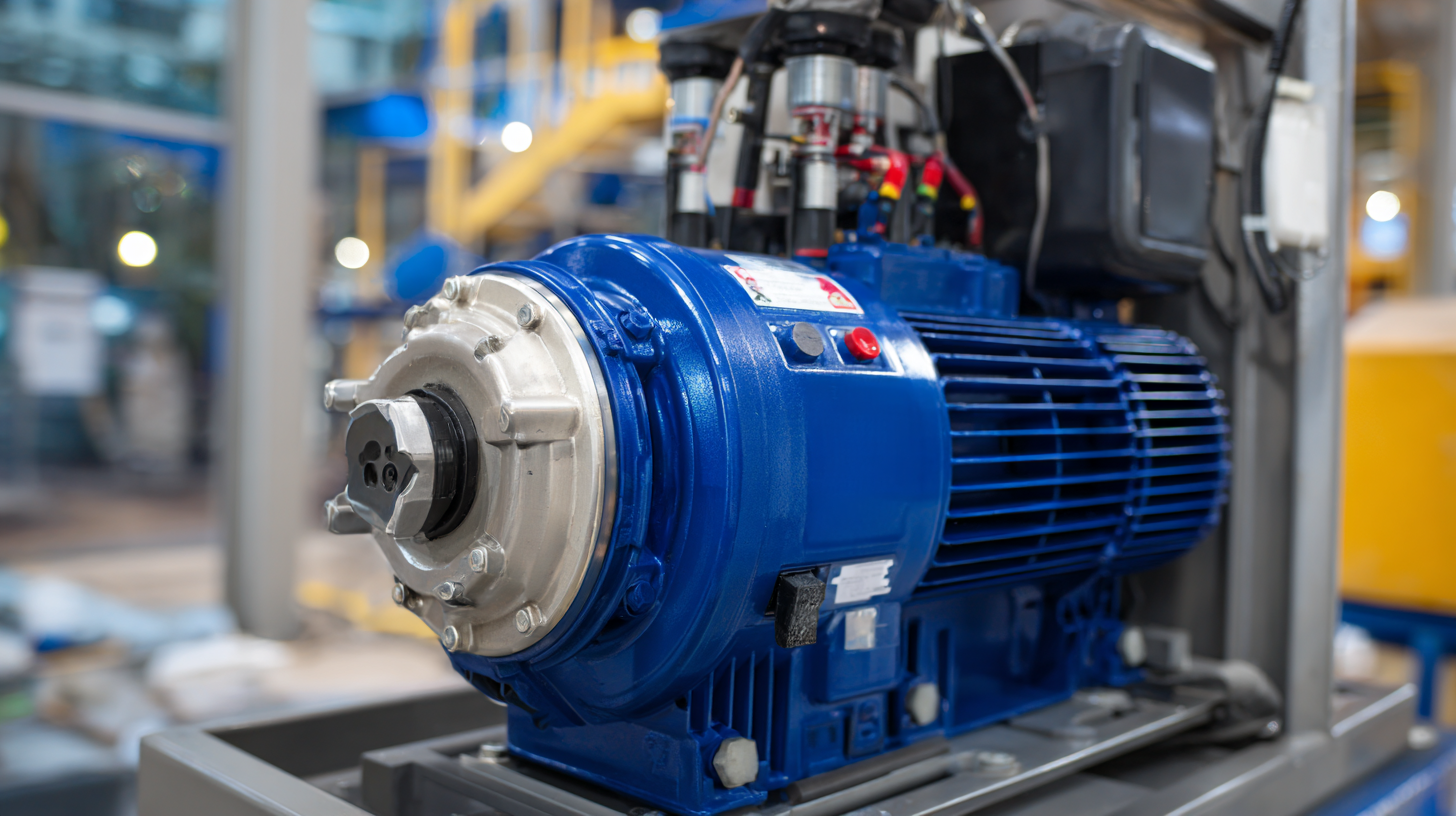

In today's industrial landscape, optimizing the efficiency of electric motor VFD (Variable Frequency Drives) is more critical than ever, particularly as energy costs continue to rise.

According to the U.S. Department of Energy, electric motors account for approximately 65% of the total energy consumed in industrial applications, with VFDs being an essential technology for enhancing performance and energy savings.

A recent report by the International Energy Agency highlights that properly implemented variable frequency drives can result in efficiency improvements of 20% or more in motor systems.

Given these statistics, it is imperative for industries to focus on optimizing their electric motor VFD systems to not only reduce energy consumption but also improve operational performance.

In this blog, we will explore seven essential tips that can help you maximize the efficiency of your electric motor VFD, ensuring a sustainable and cost-effective approach to motor management.

In today's industrial landscape, optimizing the efficiency of electric motor VFD (Variable Frequency Drives) is more critical than ever, particularly as energy costs continue to rise.

According to the U.S. Department of Energy, electric motors account for approximately 65% of the total energy consumed in industrial applications, with VFDs being an essential technology for enhancing performance and energy savings.

A recent report by the International Energy Agency highlights that properly implemented variable frequency drives can result in efficiency improvements of 20% or more in motor systems.

Given these statistics, it is imperative for industries to focus on optimizing their electric motor VFD systems to not only reduce energy consumption but also improve operational performance.

In this blog, we will explore seven essential tips that can help you maximize the efficiency of your electric motor VFD, ensuring a sustainable and cost-effective approach to motor management.

Understanding VFD Efficiency: Key Metrics and Industry Standards for Electric Motors

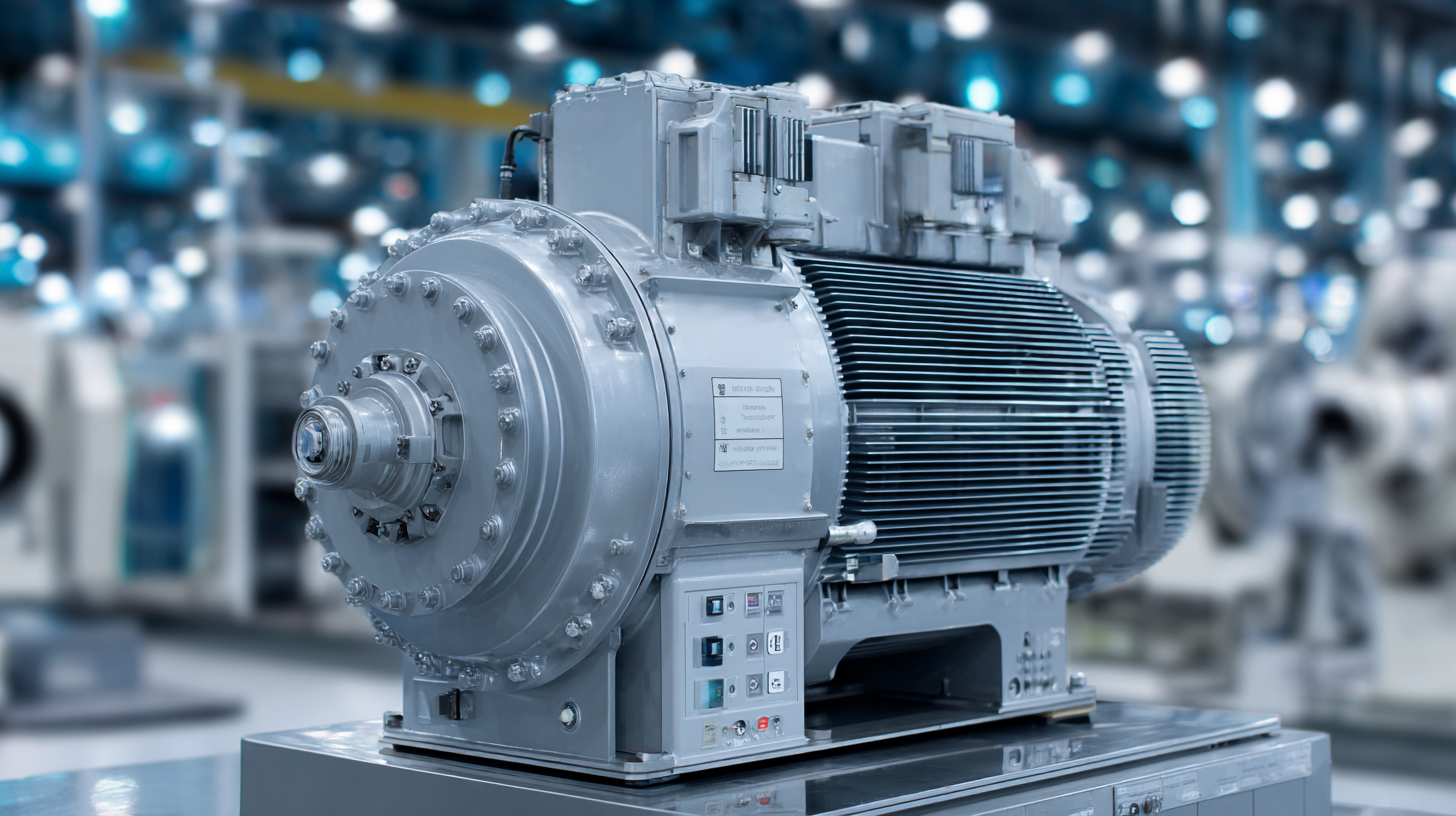

When it comes to optimizing the efficiency of electric motor variable frequency drives (VFDs), understanding key metrics and industry standards is crucial. Efficiency metrics such as power factor, total harmonic distortion (THD), and efficiency rating significantly affect the performance and operational cost of electric motors. A high power factor indicates better utilization of electrical power, while low THD helps reduce energy losses and equipment wear. Adhering to established industry standards, such as those set by the Institute of Electrical and Electronics Engineers (IEEE) and the National Electrical Manufacturers Association (NEMA), can ensure optimal performance and compliance with efficiency regulations.

To achieve the best efficiency, it's essential to consider how these metrics interplay with the overall system design. For instance, an integrated approach that evaluates both the motor and the VFD allows for better compatibility and performance. Regular monitoring and maintenance of both components can further ensure they operate within their designated efficiency parameters. By focusing on these key metrics and adhering to industry standards, businesses can enhance their VFD performance, reduce energy consumption, and ultimately achieve significant cost savings.

Identifying Common VFD Efficiency Losses: Data-Driven Insights for Optimizing Performance

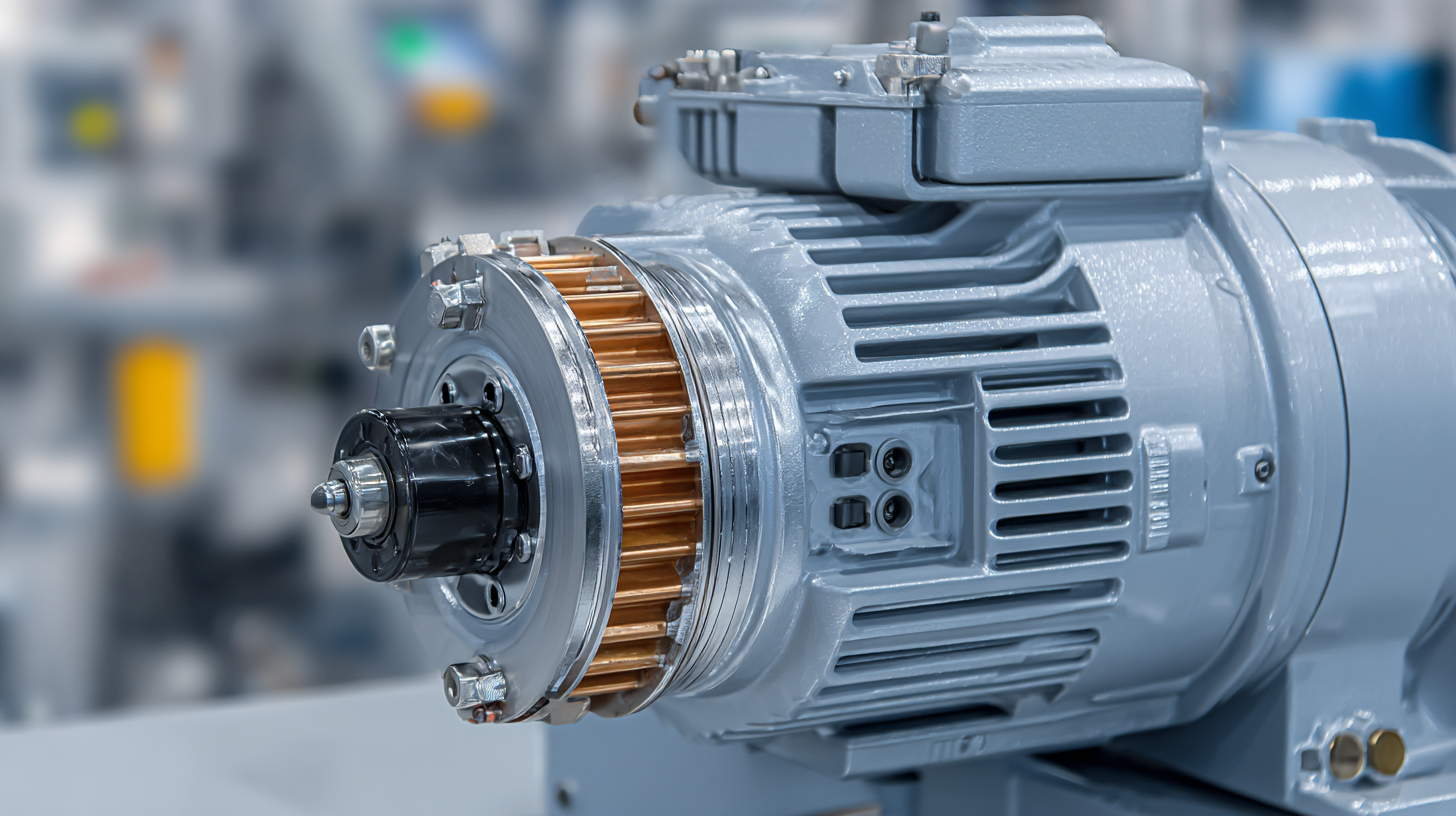

When it comes to optimizing the efficiency of Variable Frequency Drives (VFDs), identifying common efficiency losses is crucial. Data-driven insights reveal that one of the primary sources of inefficiency stems from improper VFD ratings. Ensuring that the VFD is correctly sized for your electric motor can significantly reduce energy waste. A VFD that is too large can lead to excessive harmonics, while an undersized unit may struggle under load, causing premature failure.

Another common pitfall is neglecting regular maintenance and monitoring. It's essential to regularly check the performance parameters and ensure that the VFD is operating within its optimal range. Implementing a routine maintenance schedule helps catch potential issues early and maintains peak performance. Additionally, consider upgrading to advanced sensors that provide real-time data on VFD operation, enabling more informed decision-making.

Lastly, be mindful of the surrounding environment in which the VFD operates. Factors such as ambient temperature and ventilation can greatly influence efficiency. Maintaining optimal conditions can enhance performance and extend the lifespan of your equipment. By focusing on these areas, you can effectively optimize VFD efficiency and improve your overall energy management strategy.

7 Essential Tips for Optimizing Your Electric Motor VFD Efficiency

| Efficiency Loss Factor | Common Causes | Potential Loss Percentage | Optimization Tip |

|---|---|---|---|

| Harmonics | Non-linear loads in the system | 5-20% | Install harmonic filters |

| Voltage Imbalance | Unequal phase voltages | 2-10% | Balance the supply voltage |

| Cable Losses | Resistance in cables | 3-12% | Use appropriately sized cables |

| VFD Output Filters | Improper configuration | 4-15% | Properly match filters to the motor |

| Cooling Losses | Inadequate cooling systems | 5-15% | Improve ventilation and heat dissipation |

| Control Strategy | Suboptimal settings | 3-8% | Regularly review and adjust control algorithms |

| Load Matching | Mismatch between motor and load | 2-10% | Assess and adjust load requirements |

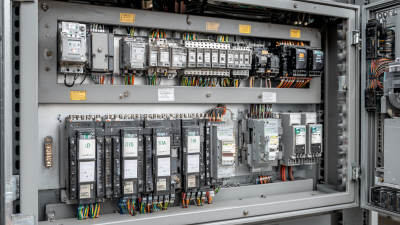

Implementing Regular Maintenance: Statistical Benefits to VFD Lifespan and Efficiency

Implementing regular maintenance for Variable Frequency Drives (VFDs) is crucial for maximizing both their lifespan and operational efficiency. Research from the Electric Power Research Institute indicates that proper maintenance can enhance VFD efficiency by up to 15%, leading to significant reductions in energy costs over time. This statistic highlights the financial incentives for businesses to prioritize maintenance, ensuring that their VFDs are functioning at optimal levels. Regular assessments can identify issues such as overheating, which is noted to reduce a VFD’s lifespan by approximately 40% if left unaddressed.

Implementing regular maintenance for Variable Frequency Drives (VFDs) is crucial for maximizing both their lifespan and operational efficiency. Research from the Electric Power Research Institute indicates that proper maintenance can enhance VFD efficiency by up to 15%, leading to significant reductions in energy costs over time. This statistic highlights the financial incentives for businesses to prioritize maintenance, ensuring that their VFDs are functioning at optimal levels. Regular assessments can identify issues such as overheating, which is noted to reduce a VFD’s lifespan by approximately 40% if left unaddressed.

Moreover, the Institute of Electrical and Electronics Engineers reports that timely maintenance can increase the operational life of VFDs by an average of 25%. Such improvements not only mitigate the need for premature replacements but also contribute positively to the overall sustainability of operations. Regularly scheduled inspections, along with cleaning and component checks, facilitate the detection of potential problems before they escalate, ultimately enhancing reliability and efficiency. By investing in a robust maintenance strategy, companies position themselves to enjoy widespread benefits that extend beyond mere cost savings.

Utilizing Advanced Control Techniques: Innovations in Boosting VFD Efficiency and Reducing Waste

In the rapidly evolving landscape of industrial technology, advanced control techniques stand at the forefront of optimizing the efficiency of Variable Frequency Drives (VFDs). These innovations not only enhance motor performance but also significantly reduce energy waste. By integrating sophisticated algorithms and analytics, industries can fine-tune the operation of their electric motors, leading to more precise control over speed and torque. This is particularly crucial in sectors like textile manufacturing, where automation is reshaping production lines to minimize human intervention and streamline processes.

Moreover, as industries grapple with sustainability challenges, optimizing VFD efficiency becomes imperative. In agricultural contexts, for instance, effective motor control systems can help reduce post-harvest losses by improving the efficiency of agro-processing equipment. By employing state-of-the-art VFDs, manufacturers can ensure that their operations are not only cost-effective but also environmentally responsible, addressing the pressing need for sustainable development. Embracing these advanced techniques will pave the way for a smarter industry that better aligns with both economic and ecological objectives.

Energy Savings through Smart Monitoring: Real-Time Data Applications to Enhance VFD Performance

In today's industrial landscape, optimizing the efficiency of electric motor VFDs (Variable Frequency Drives) is crucial for energy conservation. Real-time data applications play a pivotal role in enhancing VFD performance and maximizing energy savings. By continuously monitoring key parameters, businesses can adapt their operational strategies to ensure peak efficiency and reduced energy costs.

One important tip for optimizing VFD efficiency is to implement smart monitoring tools that provide real-time insights. These tools help in identifying inefficiencies and potential issues in the system before they escalate into costly downtime. Another effective strategy is to regularly analyze the data collected to fine-tune the system's performance settings, ensuring that motors are operating within their optimal range.

Additionally, integrating predictive analytics can lead to proactive maintenance, which is essential for sustaining performance and preventing energy waste. By anticipating maintenance needs through data analysis, companies can avoid unexpected failures and improve the overall lifespan of their electric motors. Embracing these smart technologies not only enhances VFD efficiency but also significantly contributes to long-term energy savings and operational sustainability.

Related Posts

-

How to Effectively Select the Right Motor Starter for Your Industrial Needs

-

Top Strategies for Enhancing Circuit Breaker Performance and Reliability in Industrial Applications

-

9 Essential Tips for Maintaining Your Electrical Breakers

-

5 Essential Benefits of Upgrading Your Electrical Switchgear for Global Industry Leaders

-

Essential Guide to Optimizing Industrial Motors with 3 Phase Soft Starters

-

How to Choose the Right Electrical Switchgear for Your Industrial Needs