Maximizing Efficiency: How Advanced Motor Starters Improve Energy Consumption in Industrial Applications

In today's industrial landscape, maximizing energy efficiency is not just a goal but a necessity driven by rising operational costs and strict environmental regulations. Advanced motor starters play a crucial role in this endeavor, as evidenced by a report from the International Energy Agency, which estimates that motor systems account for nearly 70% of industrial electricity consumption. By utilizing smart motor starters equipped with various control technologies, industries can significantly reduce energy waste during the startup phase and operation of electric motors. Furthermore, according to a study by the U.S. Department of Energy, implementing these state-of-the-art motor starters can lead to energy savings of 15-30% compared to traditional methods. As manufacturers seek to optimize their processes while adhering to sustainability commitments, understanding how to leverage motor starters effectively becomes paramount for enhancing operational efficiency and reducing the overall carbon footprint.

Understanding Advanced Motor Starters and Their Role in Energy Management

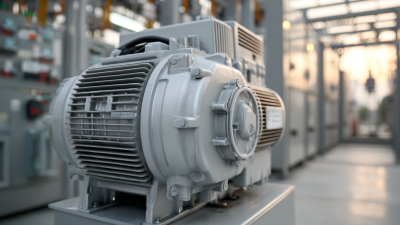

Advanced motor starters are playing a crucial role in energy management within industrial applications, particularly as industries seek to optimize energy consumption in response to increasing electricity demands. The Direct on Line (DOL) motor starter market is experiencing notable growth, driven by the simplicity and effectiveness of these starters in various industrial settings. Reports indicate that as industrial electrification continues to surge, the demand for efficient motor operation is expected to rise significantly, providing an opportunity for advanced motor starters to minimize energy waste and enhance overall system performance.

In regions like Asia-Pacific, the implementation of stringent energy efficiency regulations is fostering advancements in motor-driven systems, promoting the adoption of modern starter technologies. By integrating energy storage systems within photovoltaic setups, industries can reduce electricity costs while improving the reliability and flexibility of their power supplies. This synergy not only aids in meeting regulatory standards but also enhances sustainability efforts across sectors.

Tips: When selecting advanced motor starters, consider the specific needs of your system and look for features that promote energy efficiency, such as variable frequency drives. Regular maintenance of motor systems can also yield significant energy savings, ensuring that your operations remain both cost-effective and environmentally friendly.

The Impact of Energy Efficiency on Industrial Operational Costs

In the realm of industrial operations, energy efficiency plays a pivotal role in determining overall operational costs. Advanced motor starters significantly enhance energy consumption by optimizing the performance of electric motors, which are often the largest consumers of energy in manufacturing facilities. These motor starters incorporate sophisticated technologies that allow for smoother motor starts, reduced inrush currents, and better speed control. By minimizing energy waste during motor operation, businesses can substantially lower their energy bills, contributing to a healthier bottom line.

Furthermore, investing in energy-efficient motor starters can lead to improvements in equipment lifespan and reduction in maintenance needs. As motors operate more smoothly and with less strain, wear and tear is drastically diminished, leading to fewer breakdowns and costly repairs. This not only cuts maintenance costs but also ensures higher productivity levels as machines remain operational for longer periods. Overall, the integration of advanced motor starters not only serves to reduce energy consumption but also enhances the overall cost-effectiveness of industrial operations by streamlining both energy expenditure and maintenance efforts.

Key Technologies in Advanced Motor Starters Enhancing Performance

Advanced motor starters play a crucial role in enhancing the efficiency of industrial applications by incorporating key technologies. One significant advancement is the use of soft starters, which gradually ramp up motor voltage and current, reducing mechanical stress during startup. This technology minimizes energy spikes that can occur during abrupt start-ups, thus enhancing the overall energy consumption profile of industrial systems. It not only prolongs the lifespan of motors but also reduces maintenance costs associated with wear and tear.

Another pivotal technology in advanced motor starters is variable frequency drives (VFDs). VFDs allow precise control over motor speed and torque, facilitating optimal energy use depending on the load requirement. This adaptability results in substantial energy savings, especially in applications with varying demand, such as pumps and fans. Furthermore, the integration of smart sensors and IoT capabilities into motor starters enables real-time monitoring and data collection, providing valuable insights for predictive maintenance and operational efficiency. Collectively, these innovations not only boost performance but significantly reduce energy consumption, aligning with sustainability goals in modern industrial settings.

Comparative Analysis: Traditional vs. Advanced Motor Starters in Energy Consumption

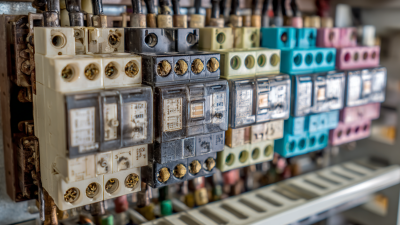

In the realm of industrial applications, energy consumption remains a critical aspect of operational efficiency. Traditional motor starters, while reliable, often lead to higher energy costs due to their lack of advanced features. These conventional systems typically operate in a simple on/off manner, which results in high inrush currents and unnecessary wear on motors. Consequently, they can contribute to energy wastage, leading to increased operational expenses and potentially damaging equipment longevity.

In contrast, advanced motor starters come equipped with various technologies like soft starting, variable frequency drives, and intelligent monitoring systems. These features enable more controlled motor operations, minimizing the initial surge of energy when a motor kicks on. For instance, soft starters gradually ramp up the voltage, reducing mechanical stress and enhancing energy efficiency. Additionally, the capability for real-time monitoring allows businesses to analyze energy consumption patterns and make data-driven adjustments. This comparative efficiency illustrates how investing in advanced motor starters not only optimizes energy use but also supports sustainable practices in industrial environments.

Real-World Case Studies: Success Stories of Efficiency Gains in Industry

Advanced motor starters are emerging as pivotal components in enhancing energy efficiency within industrial applications. Real-world case studies reveal that companies leveraging these technologies have achieved significant reductions in energy consumption and operational costs. For instance, a recent industry report indicated that organizations implementing advanced motor control solutions reported energy savings of up to 30%. This not only boosts their bottom line but also contributes to broader sustainability efforts.

With the integration of AI technologies, industrial sectors are witnessing transformative efficiency gains. AI-driven predictive maintenance ensures that equipment operates at optimal levels, reducing downtime and energy wastage. A notable case study highlighted that a leading manufacturing firm reduced operational costs by 20% by adopting smart motor starters in tandem with AI solutions, thus enhancing overall productivity. This alignment of advanced motor systems and AI showcases a powerful synergy that can drive innovation and efficiency in manufacturing processes.

**Tips:** To maximize efficiency with advanced motor starters, consider implementing predictive maintenance strategies that leverage AI capabilities to preempt equipment failures. Additionally, regularly monitor energy consumption patterns to identify further optimization opportunities. Investing in training for staff on these advanced technologies can also lead to quicker adaptability and efficiency gains.

Maximizing Efficiency: Energy Consumption Reduction with Advanced Motor Starters

Related Posts

-

How to Effectively Select the Right Motor Starter for Your Industrial Needs

-

Essential Checklist for Choosing the Right Motor Starters in Global Supply Chains

-

Exploring Manual Motor Starter Innovations at the 138th China Import and Export Fair in 2025

-

How to Optimize Electric Motor Controller Performance for Maximum Energy Efficiency

-

How to Choose the Right Circuit Breaker for Your Home Electrical System

-

How to Choose the Right Circuit Breakers for Your Electrical System Needs