Understanding Soft Starters: The Key to Smooth Motor Operation and Enhanced Energy Efficiency

In the realm of industrial motor control, the integration of soft starters has emerged as a transformative solution that enhances energy efficiency and promotes smoother operation. As defined by industry expert Dr. Jane Smith, a leading authority in electrical engineering, “Soft starters are essential for reducing mechanical stress on motors and extending their operational lifespan.” This statement underscores the fundamental role that soft starters play in modern motor applications.

The increasing demand for energy-efficient solutions has prompted manufacturers to seek innovative technologies that not only optimize performance but also minimize energy consumption. Soft starters, which gradually ramp up the voltage to a motor, significantly reduce the inrush current during startup, preventing undesirable effects such as torque shocks and electrical stress. By improving the startup process, these devices contribute to the overall reliability and longevity of motor systems.

Furthermore, the adoption of soft starters aligns with global efforts to reduce carbon footprints and operating costs. As industries strive for sustainability, understanding the advantages of soft starters becomes paramount. This article delves into the pivotal benefits of soft starters, highlighting their role in achieving enhanced motor operation and energy savings, paving the way for a more efficient future in motor control technology.

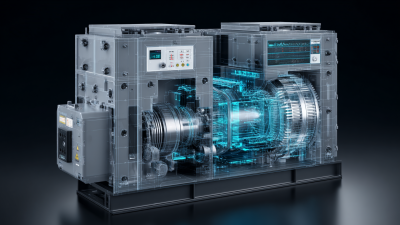

What is a Soft Starter and How Does It Work?

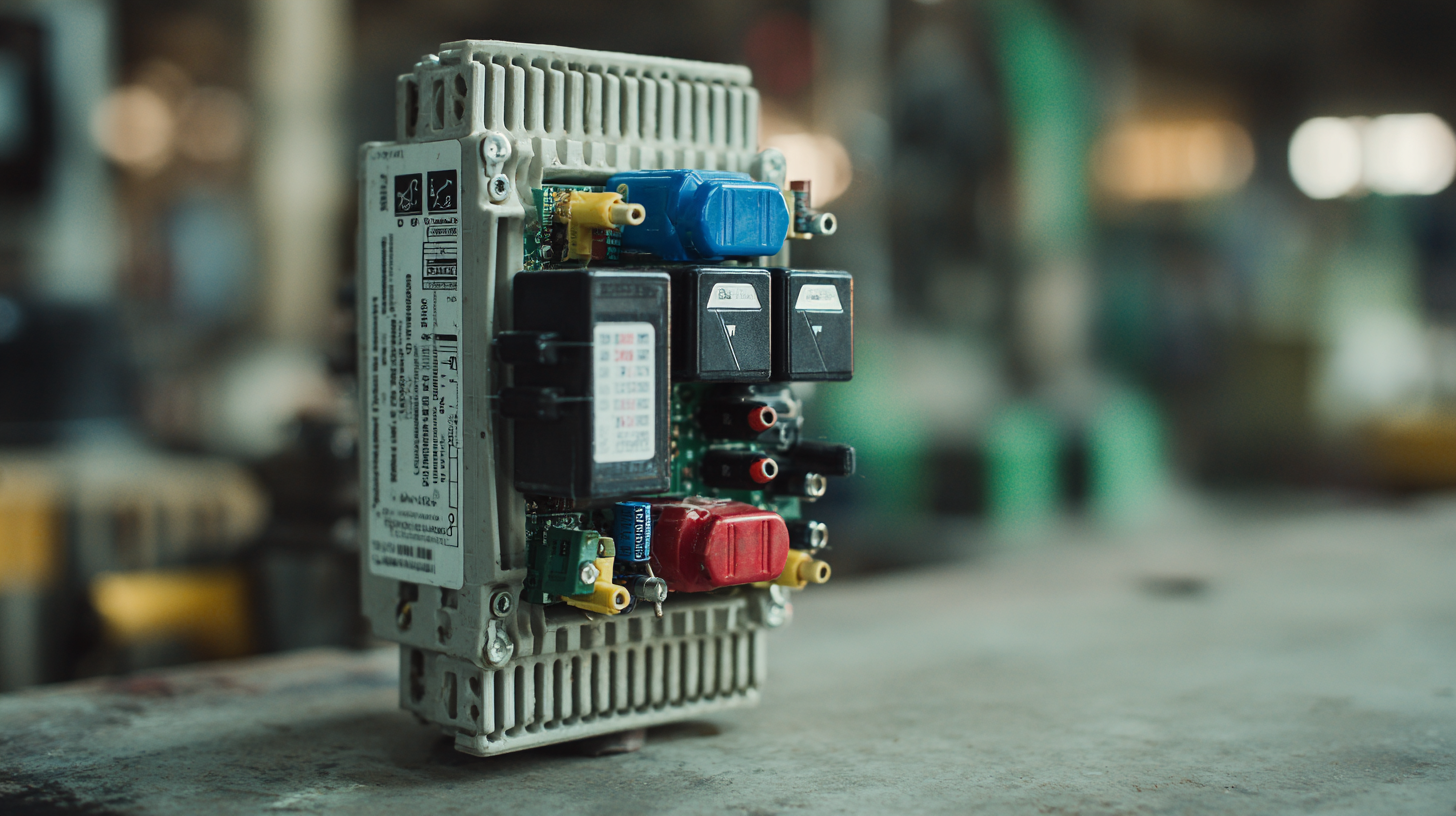

A soft starter is an essential device used in electrical motor applications to control the start-up of the motor, thereby reducing the initial inrush current that can damage the motor and connected equipment. By gradually ramping up the voltage supplied to the motor, soft starters provide a smoother acceleration phase, which not only enhances the lifespan of the motor but also minimizes mechanical stress on the entire system.

A soft starter is an essential device used in electrical motor applications to control the start-up of the motor, thereby reducing the initial inrush current that can damage the motor and connected equipment. By gradually ramping up the voltage supplied to the motor, soft starters provide a smoother acceleration phase, which not only enhances the lifespan of the motor but also minimizes mechanical stress on the entire system.

In addition to motor protection, advancements in technology, such as those seen in the development of new components for 48V systems, showcase the integration of sophisticated features like voltage monitoring and logical decision-making for braking. These innovations align with the core functions of soft starters, emphasizing the importance of diagnostics and protection mechanisms in modern electric drives. By ensuring a controlled and efficient start, soft starters contribute significantly to energy efficiency, reducing wasted energy during startup and optimizing overall operational performance.

The Benefits of Using Soft Starters in Motor Applications

Soft starters are pivotal in enhancing the performance and energy efficiency of various motor applications. By moderating the inrush current during motor startups, these devices protect motors and connected equipment from potential damage, thereby extending their operational lifespan. As industries seek to comply with increasing energy efficiency mandates, the adoption of soft starters has surged. These devices play a critical role in reducing energy consumption, which not only lowers operational costs but also contributes to environmentally sustainable practices.

Tips for choosing the right soft starter include ensuring that it is appropriately sized for your specific motor application. An oversized or undersized soft starter can lead to inefficient operation and diminished effectiveness. Additionally, consider the operational environment; for example, some soft starters may be better suited for harsh industrial conditions than others.

With innovations in soft starter technology, such as new generation models and medium voltage options, businesses now have access to more efficient solutions tailored to their unique needs. By staying informed about these advancements, organizations can leverage the benefits of soft starters, achieving a smooth motor operation while minimizing energy costs and environmental impacts.

Understanding Soft Starters: Motor Operation Efficiency

This chart demonstrates the significant reduction in energy consumption when soft starters are utilized in motor applications. The data illustrates that energy usage drops from 150 kWh to 100 kWh, showcasing the efficiency benefits of integrating soft starters into motor systems.

Step-by-Step Guide to Installing a Soft Starter

Installing a soft starter can significantly improve the efficiency and lifespan of electric motors. A soft starter is a crucial component that allows for a gradual increase in motor voltage during startup, reducing mechanical stress, electrical surges, and energy consumption. According to industry data, utilizing a soft starter can lead to energy savings of up to 30%, making it an essential investment for industrial applications.

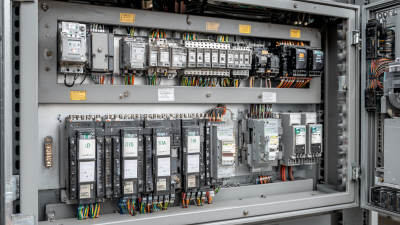

To install a soft starter, start by ensuring that you have the appropriate tools and protective equipment. Check the motor specifications and select a soft starter compatible with your system's voltage and current ratings. Begin the installation by disconnecting power to the motor and safely positioning the soft starter in line with the motor circuit. Connect the input side of the soft starter to the power supply and the output side to the motor, following the provided wiring diagram meticulously to avoid potential hazards.

Once the connections are made, perform a thorough inspection before restoring power. After booting up the system, adjust the soft starter settings according to your motor's requirements, including start time, stop time, and ramp-up/reduced voltage settings. Testing the system to ensure proper operation will confirm that the installation was successful and that your motor can now operate smoothly and efficiently.

Common Mistakes to Avoid When Using Soft Starters

When utilizing soft starters for motor operation, avoiding common pitfalls is essential to maximize efficiency and performance. One significant mistake is neglecting proper sizing of the soft starter. According to a report by the International Electrotechnical Commission (IEC), improperly sized soft starters can lead to overheating and premature failure, with up to 30% of installations experiencing issues due to inadequate ratings. It’s crucial to ensure that the starter's current rating matches the motor’s specifications, including starting and running load conditions.

Another frequent error is failing to adjust the start-up parameters adequately. Soft starters allow for customizable settings that can significantly impact motor performance, yet many users stick to factory defaults. A study by the U.S. Department of Energy highlights that fine-tuning these parameters can improve energy efficiency by as much as 15%, reducing operational costs. Users should take the time to understand the load characteristics and select the optimal starting time and ramp-up voltage to prevent unnecessary strain on the motor and connected equipment.

Lastly, overlooking the necessity of routine maintenance can be detrimental. Reports from the Electric Power Research Institute (EPRI) indicate that regular checks on soft starter components, including bypass contactors and control circuits, can prolong equipment life and maintain efficiency. By addressing these common mistakes, operators can ensure not only smooth motor operation but also significant energy savings in the long run.

Understanding Soft Starters: The Key to Smooth Motor Operation and Enhanced Energy Efficiency - Common Mistakes to Avoid When Using Soft Starters

| Issue | Description | Impact | Solution |

|---|---|---|---|

| Incorrect Sizing | Using a soft starter that does not match the motor's capacity. | May cause overheating or inadequate control. | Always ensure proper sizing based on motor specifications. |

| Overlooking Control Settings | Failing to adjust control parameters for specific applications. | Can lead to excessive current draw or slow acceleration. | Review and adjust settings based on load requirements. |

| Neglecting Maintenance | Ignoring routine checks on connections and components. | Can lead to performance deterioration and failures. | Establish a regular maintenance schedule. |

| Improper Installation | Incorrect wiring or placement of the soft starter. | May cause erratic motor operation or damage. | Follow manufacturer guidelines closely during installation. |

| Ignoring Ambient Conditions | Not considering environmental factors like temperature and humidity. | Can affect the efficiency and lifespan of the soft starter. | Install in a suitable environment, choosing appropriate enclosures if needed. |

Tips for Optimizing Energy Efficiency with Soft Starters

Soft starters play a crucial role in optimizing energy efficiency during motor operation. By gradually ramping up the voltage supplied to the motor, they help to minimize inrush currents that can lead to excessive energy consumption. According to a report by the Electric Power Research Institute (EPRI), using a soft starter can reduce starting current by up to 70%, which significantly lessens the electrical demand and mitigates potential damage to motor components. This efficient initial operation also contributes to reduced wear and tear on mechanical systems, prolonging their lifespan and thus leading to lower maintenance costs.

To fully harness the benefits of soft starters, operators can implement several optimization tips. Firstly, selecting a soft starter with appropriate ratings and features for the specific motor can enhance efficiency. Additionally, integrating advanced control strategies, such as torque control and customizable trip settings, can optimize performance under varying load conditions. A study by the Institute of Electrical and Electronics Engineers (IEEE) suggests that these configurations can lead to an additional 10-15% improvement in energy savings for industries that experience fluctuating demands. By prioritizing these strategies, facilities can not only enhance their energy efficiency but also contribute to broader sustainability goals in industrial operations.

Related Posts

-

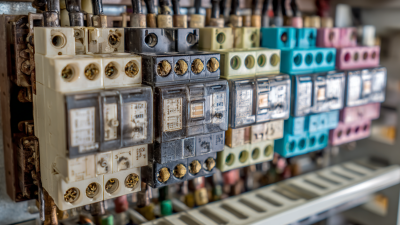

How to Choose the Right Circuit Breakers for Your Electrical System Needs

-

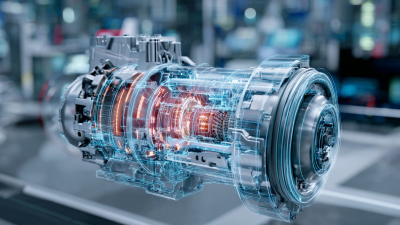

Understanding the Benefits of VFD Drive Technology in Modern Industries

-

Understanding the Future of Motors and Controls in Sustainable Technology

-

How to Choose the Right Electrical Switchgear for Your Industrial Needs

-

Essential Checklist for Choosing the Right Motor Starters in Global Supply Chains

-

Unlocking the Power of Frequency Drives for Energy Efficient Automation Solutions