Understanding Electrical Switchgear: Key Innovations Shaping the Future of Power Distribution

In recent years, the evolution of electrical switchgear has been pivotal in transforming the landscape of power distribution, driven by technological innovations and heightened demand for reliability and efficiency. According to a report by MarketsandMarkets, the global electrical switchgear market is projected to reach $210 billion by 2026, growing at a CAGR of 6.5% from 2021. This surge is largely fueled by the increasing implementation of smart grids and renewable power sources, necessitating advanced switchgear solutions that ensure seamless integration and operational efficiency. Furthermore, industry standards are progressively emphasizing safety and sustainability, pushing manufacturers to innovate in the design and functionality of electrical switchgear. As we delve into the key innovations that are shaping the future of electrical switchgear, it becomes evident that staying abreast of these trends is essential for stakeholders looking to enhance the resilience and efficiency of power distribution networks.

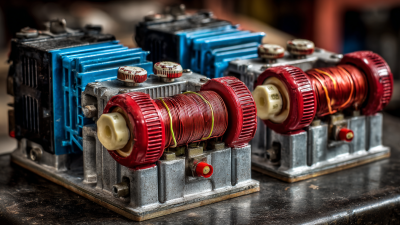

Innovative Materials and Technologies in Modern Electrical Switchgear

The evolution of electrical switchgear is significantly influenced by innovative materials and technologies, which are redefining the landscape of power distribution. Advanced insulating materials, such as epoxy resin and silicone rubber, enhance the performance and safety of switchgear systems. These materials not only provide superior insulation properties but also exhibit remarkable resistance to environmental factors, such as humidity and temperature fluctuations, thereby extending the lifespan of the equipment.

The evolution of electrical switchgear is significantly influenced by innovative materials and technologies, which are redefining the landscape of power distribution. Advanced insulating materials, such as epoxy resin and silicone rubber, enhance the performance and safety of switchgear systems. These materials not only provide superior insulation properties but also exhibit remarkable resistance to environmental factors, such as humidity and temperature fluctuations, thereby extending the lifespan of the equipment.

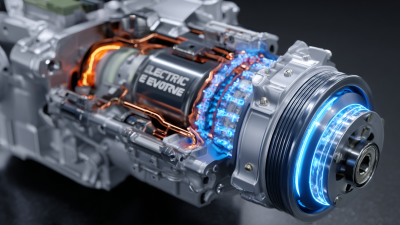

Moreover, the integration of smart technologies into switchgear systems is revolutionizing how electrical networks are managed. With the advent of digital monitoring and automation, operators can gain real-time insights into system performance, enabling proactive management and rapid response to potential issues. Innovations like gas-insulated switchgear (GIS) contribute to space efficiency and increased reliability, making it an attractive option for urban settings. Overall, the combination of advanced materials and cutting-edge technologies is driving significant enhancements in switchgear design, leading to greater efficiency and resilience in power distribution networks.

Integrating Smart Features for Enhanced Monitoring and Control

The rapid evolution of electrical switchgear technology is significantly influenced by the integration of smart features designed for enhanced monitoring and control. Data from the International Energy Agency (IEA) indicates that intelligent monitoring systems can reduce operational costs by up to 30% and improve reliability by providing real-time insights into system performance. These innovations enable utilities to detect faults more swiftly and optimize maintenance schedules, ultimately extending the lifespan of switchgear assets.

Moreover, the global smart switchgear market is projected to reach $15 billion by 2026, with a compound annual growth rate (CAGR) of 10.5% according to a report by MarketsandMarkets. This surge underscores the growing demand for digitized components that incorporate advanced analytics and automated controls. Such features not only enhance the efficiency of power distribution but also support the integration of renewable energy sources, thereby aligning with global sustainability goals.

The shift towards smart switchgear is paving the way for more resilient and flexible energy systems, essential for meeting future energy demands.

Advancements in Safety Standards and Regulations for Switchgear

The landscape of electrical switchgear is rapidly evolving, driven largely by advancements in safety standards and regulations. As the demand for reliable and efficient power distribution systems grows, so too does the need for enhanced safety measures. Recent innovations have led to the development of switchgear that meets stricter standards, ensuring both operational safety and environmental sustainability. Manufacturers are now focusing on integrating smart technology, which not only improves performance but also aids in compliance with regulatory frameworks.

**Tips:** When selecting switchgear, always check for compliance with the latest safety regulations to ensure maximum protection and efficiency. Regular training for personnel on updated safety practices is crucial for minimizing risks associated with electrical systems.

A significant shift towards digital monitoring and maintenance has also impacted safety protocols. Modern switchgear designs often incorporate sensors and analytics that provide real-time insights into the system’s health. This proactive approach enables faster response times to potential hazards, fostering a safer working environment. Moreover, organizations are increasingly prioritizing self-healing technologies to enhance reliability and decrease downtime.

**Tips:** Implement a regular inspection and maintenance schedule to align with updated regulations. Leverage technology for predictive maintenance to identify potential issues before they lead to failures.

Advancements in Safety Standards for Electrical Switchgear

This chart illustrates the increasing number of safety innovations in electrical switchgear from 2018 to 2023, showcasing a significant rise in advancements that enhance power distribution safety standards.

Eco-Friendly Practices in Switchgear Design and Implementation

The shift towards eco-friendly practices in switchgear design and implementation is increasingly becoming a focal point in the power distribution industry.

The high voltage oil-insulated switchgear market is projected to exceed USD 1 billion in 2024, with a compound annual growth rate (CAGR) of 5.8% anticipated from 2025 to 2034. This growth is driven not only by advancements in technology but also by a commitment to reducing environmental impact, particularly in eliminating substances like sulfur hexafluoride (SF6) gas, which poses significant environmental challenges.

Moreover, the global low-voltage (LV) and medium-voltage (MV) switchgear market is expected to grow from USD 393.59 billion in 2024 to USD 597.13 billion by 2033, reflecting a robust demand for sustainable solutions. As industries and utilities recognize the urgent need to combat climate change, there is a notable trend of adopting SF6-free switchgear alternatives. This shift highlights the pivotal role that substations and switchgear play in managing energy flow efficiently while adhering to environmentally responsible practices that promote sustainability in the power sector.

Future Trends in Electrical Switchgear for Smart Grids and Renewable Energy

In the evolving landscape of power distribution, electrical switchgear is poised to play a pivotal role in the proliferation of smart grids and the integration of renewable energy sources. The shift towards decentralized energy systems necessitates advancements in switchgear technology that can efficiently accommodate variable energy inputs from sources such as solar and wind. Smart switchgear equipped with advanced monitoring and control systems enables real-time data analysis, facilitating proactive management of energy flows and enhancing grid stability.

Moreover, the integration of digital technologies in switchgear design is driving innovations such as predictive maintenance and automation. These features not only reduce operational costs but also improve reliability and performance. As utilities transition towards more sustainable energy paradigms, the demand for intelligent switchgear solutions that enhance communication between devices and enable demand-side management becomes critical. The focus on developing eco-friendly materials and reducing energy losses further aligns with global sustainability goals, marking a significant trend in the future of electrical switchgear and its critical role within smart grids.

Understanding Electrical Switchgear: Key Innovations Shaping the Future of Power Distribution

| Innovation | Description | Impact on Power Distribution | Future Trends |

|---|---|---|---|

| Digital Switchgear | Integration of digital communication and control systems. | Enhances monitoring and fault detection capabilities. | Greater adoption of IoT technologies. |

| Smart Grid Compatibility | Switchgear designed to interface effectively with smart grid technologies. | Improved load management and energy efficiency. | Predicted increase in decentralized energy sources. |

| Modular Design | Components can be added or removed easily to meet changing requirements. | Facilitates scalability and ease of upgrades. | Trend towards customizable energy solutions. |

| Environmental Considerations | Use of eco-friendly materials and designs. | Reduces carbon footprint of electrical systems. | Compliance with global environmental standards. |

| Automation and Control | Automatic operations and remote control capabilities. | Enhances operational efficiency and reliability. | Increased integration with artificial intelligence. |

Related Posts

-

Understanding Motor Starters: Essential Components for Industrial Engine Control

-

Maximizing Efficiency: How Advanced Motor Starters Improve Energy Consumption in Industrial Applications

-

What Are the Latest Innovations in Electric Motors Driving Industry Efficiency and Sustainability

-

Unlocking Energy Efficiency: The Role of Variable Frequency Motor Controllers in Modern Industries

-

Understanding Electrical Switches: Key Innovations and Safety Tips for Every Home

-

Essential Guide to Optimizing Industrial Motors with 3 Phase Soft Starters