Unlocking Energy Efficiency: The Role of Variable Frequency Motor Controllers in Modern Industries

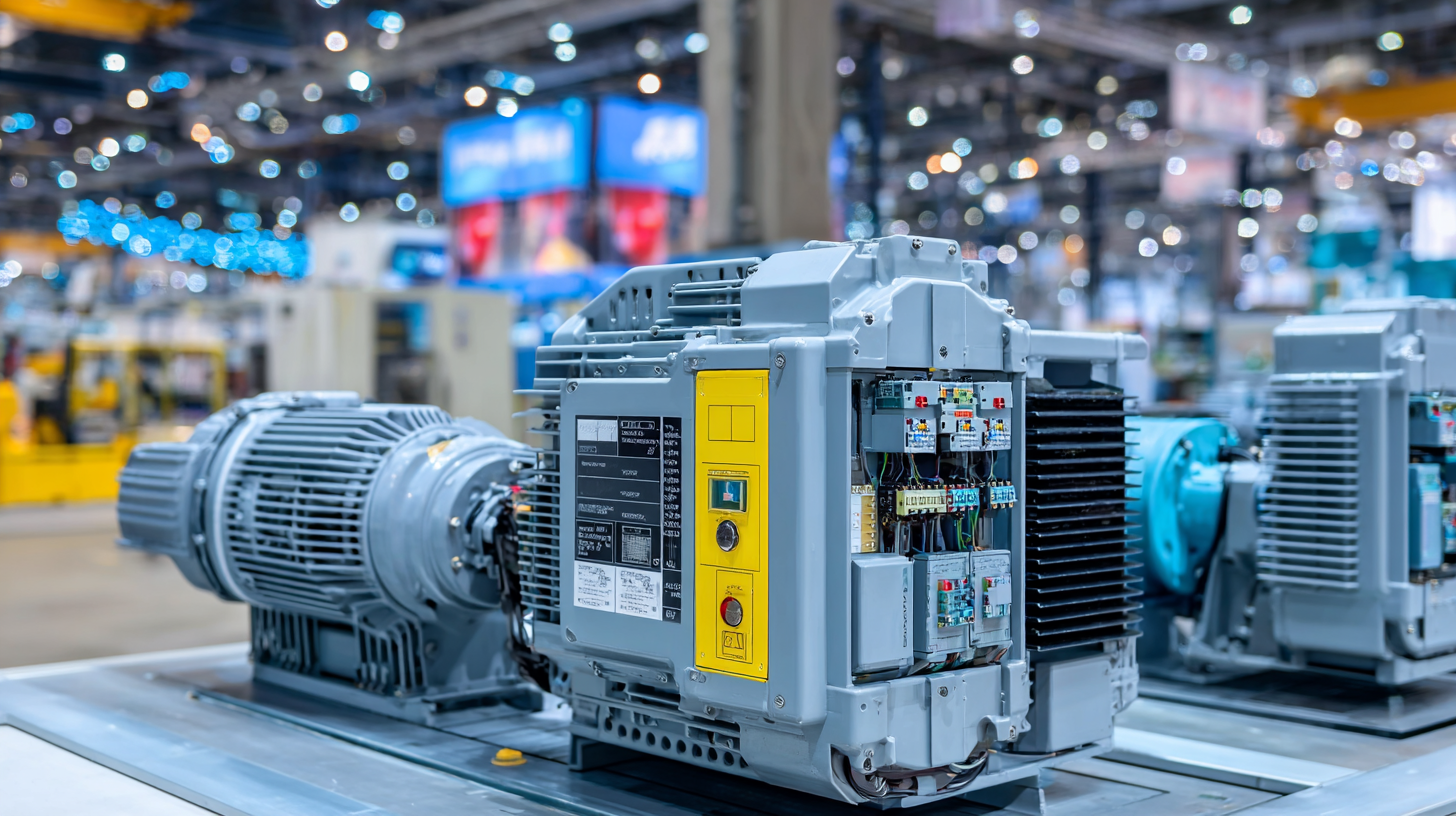

In today's rapidly evolving industrial landscape, achieving energy efficiency is paramount for sustainable operations. Variable frequency motor controllers (VFMCs) have emerged as a crucial technology in this pursuit, enabling industries to optimize motor performance and reduce energy consumption. According to a report by the International Energy Agency, motor systems account for approximately 70% of industrial electricity consumption worldwide, highlighting the significant role VFMCs play in mitigating energy waste. By allowing precise control over motor speed and torque, these controllers can enhance equipment lifespan and reduce operational costs. A study by the U.S. Department of Energy reveals that implementing variable frequency motor controllers can lead to energy savings of up to 50%, paving the way for a more efficient and eco-friendly industrial future. As industries increasingly prioritize energy efficiency, VFMCs stand out as a pivotal solution to unlock not only operational savings but also contribute to broader sustainability goals.

The Evolution of Variable Frequency Motor Controllers in Industrial Applications

The evolution of Variable Frequency Motor Controllers (VFMCs) has significantly transformed industrial applications by enhancing efficiency and optimizing performance. Originally utilized in basic speed control mechanisms, VFMCs have advanced to sophisticated systems capable of precise motor management. According to a 2021 report by Grand View Research, the global market for variable frequency drives is expected to reach $26.1 billion by 2028, with a compound annual growth rate (CAGR) of 6.3%. This growth is fueled by industries seeking to minimize energy consumption and reduce operational costs.

Furthermore, the adoption of VFMCs has enabled industries to improve productivity and sustainability. For instance, the U.S. Department of Energy notes that implementing variable frequency drives can lead to energy savings of up to 50% in various applications, such as HVAC systems and conveyor belts. This shift towards energy-efficient solutions reflects the industry's commitment to reducing carbon footprints while meeting regulatory requirements. As VFMC technology continues to evolve, its integration into modern machinery promises even greater advancements in energy efficiency and industrial performance.

Quantifying Energy Savings: Case Studies of VFDs in Manufacturing Operations

Variable Frequency Drives (VFDs) have emerged as essential tools in modern manufacturing, enabling significant energy savings through precise control of motor speed and torque. By adjusting the electrical frequency supplied to the motor, VFDs allow industries to operate more efficiently, reducing energy consumption in processes that previously ran at a constant speed. Case studies have demonstrated that facilities implementing VFDs can experience energy savings of 20% to 50%, particularly in applications such as conveyor systems, fans, and pumps, where operational demands can vary widely.

One notable case involved a large textile manufacturer that adopted VFD technology to regulate their dyeing machines. Before the installation of VFDs, the machines operated at full capacity regardless of the varying load requirements, leading to excessive energy use. After transitioning to VFDs, the company reported a staggering 30% reduction in energy costs, alongside improved product quality due to better control over the dyeing process. This shift not only enhanced their operational efficiency but also underscored the potential of VFDs to foster a more sustainable manufacturing environment, showcasing a clear pathway for sectors eager to optimize both productivity and energy consumption.

Unlocking Energy Efficiency: The Role of Variable Frequency Motor Controllers in Modern Industries - Quantifying Energy Savings: Case Studies of VFDs in Manufacturing Operations

| Industry Sector | VFD Implementation (%) | Energy Savings (%) | Cost Reduction (%) | Payback Period (months) |

|---|---|---|---|---|

| Manufacturing | 75% | 30% | 25% | 12 |

| Water Treatment | 60% | 40% | 30% | 10 |

| Textile | 80% | 35% | 20% | 8 |

| Food Processing | 70% | 28% | 22% | 11 |

| Mining | 50% | 25% | 15% | 15 |

Reducing Carbon Footprint: The Environmental Impact of Using VFDs

Variable Frequency Drives (VFDs) play a pivotal role in enhancing energy efficiency across various modern industries. By adjusting the speed of electric motors, these controllers minimize energy consumption, which directly translates to lower greenhouse gas emissions. As industrial sectors strive toward sustainability, the adoption of VFDs has emerged as a critical strategy to mitigate their carbon footprints. The capability to optimize motor operation based on real-time demand not only improves performance but also significantly reduces unnecessary energy wastage.

Variable Frequency Drives (VFDs) play a pivotal role in enhancing energy efficiency across various modern industries. By adjusting the speed of electric motors, these controllers minimize energy consumption, which directly translates to lower greenhouse gas emissions. As industrial sectors strive toward sustainability, the adoption of VFDs has emerged as a critical strategy to mitigate their carbon footprints. The capability to optimize motor operation based on real-time demand not only improves performance but also significantly reduces unnecessary energy wastage.

Moreover, the environmental impact of utilizing VFDs reaches beyond mere energy savings. By operating motors more efficiently, industries decrease overall power demand, which can lead to diminished reliance on fossil fuels and a reduction in the pollutants associated with energy production. This shift toward cleaner operational practices aligns with global sustainability goals, showcasing how integrating VFD technology can result in substantial long-term benefits for both the environment and businesses.

Adopting these controllers is thus a step forward in combating climate change and fostering a more sustainable industrial landscape.

Cost-Benefit Analysis: Return on Investment for Implementing VFD Technology

In modern industries, the implementation of Variable Frequency Drives (VFDs) has become a pivotal strategy for enhancing energy efficiency and ensuring cost-effectiveness. A techno-economic analysis indicates that systems utilizing VFDs experience significant reductions in energy consumption, particularly in operations involving fan and pump motors. Over the past two decades, the evolution of VFD technology has enabled precise control over motor speeds, leading to efficiencies that can reduce energy costs by as much as 30%, especially in continuous operation environments.

Furthermore, the financial implications of adopting VFD technology can be substantial. Recent studies have highlighted that for every $1 invested in energy efficiency measures, including VFDs, businesses can expect a return on investment (ROI) of up to $4. These savings are not only derived from reduced energy bills but also from decreased wear on equipment, which minimizes maintenance costs and extends equipment lifespan. As industries globally pursue sustainable practices, the integration of advanced technologies like VFDs presents a clear path to achieving both eco-friendly operations and improved economic viability.

Unlocking Energy Efficiency: Cost-Benefit Analysis of VFD Technology

Future Trends: Innovations in Variable Frequency Drives for Enhanced Efficiency

The evolution of variable frequency drives (VFDs) is setting the stage for significant advancements in energy efficiency across various industries. Future trends indicate a surge in the adoption of advanced algorithms and artificial intelligence that allow VFDs to optimize motor performance dynamically. By integrating real-time data analytics, modern VFDs can adjust energy consumption based on operational demands, leading to substantial energy savings and reduced carbon footprints.

Another promising innovation is the development of smart VFDs with enhanced connectivity features. The incorporation of IoT technology enables seamless communication between VFDs and other devices in a manufacturing ecosystem. This connectivity allows for improved monitoring and diagnostics, ensuring that any inefficiencies can be swiftly addressed. Furthermore, as industries push toward sustainability, VFD manufacturers are also exploring eco-friendly materials and designs, emphasizing the shift towards greener technologies in industrial applications. Together, these trends are not only enhancing efficiency but also paving the way for a more sustainable industrial future.

Related Posts

-

How to Optimize Energy Efficiency with Variable Frequency Drives in Your Facility

-

7 Tips to Optimize Your Motor Control Systems for Increased Efficiency

-

Mastering Soft Starters: A Comprehensive Guide to Enhanced Performance and Efficiency in Industrial Applications

-

Digital Revolution Best VFD Controller for Maximizing Energy Efficiency and Performance

-

Top Strategies for Maximizing Efficiency with Electrical Switch Innovations

-

How to Choose the Right Circuit Breakers for Your Home and Business Needs