Why VFD Motor Control is Essential for Modern Industrial Applications?

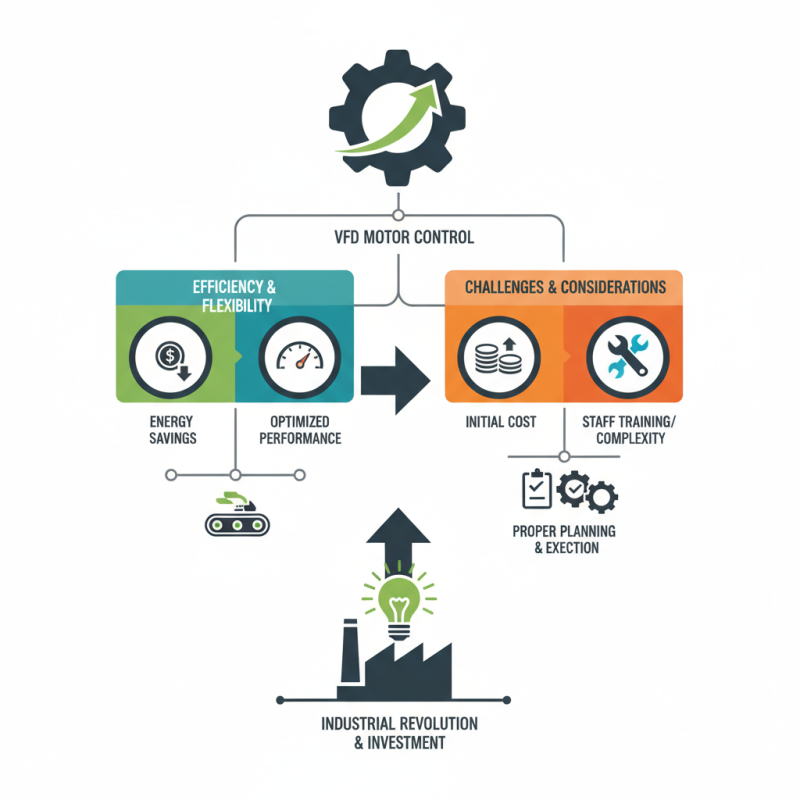

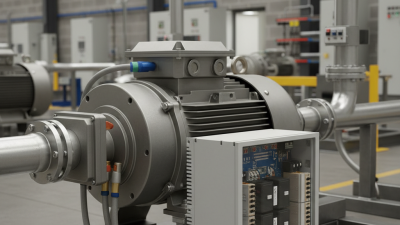

In the modern industrial landscape, VFD motor control has become a cornerstone of efficiency and flexibility. According to Dr. John Smith, an expert in motor control technology, "VFD motor control is crucial for optimizing energy consumption and enhancing operational performance." This statement captures the essence of why industries are increasingly adopting variable frequency drives.

VFD motor control adjusts the speed and torque of motors as needed. This adaptability not only reduces energy costs but also lowers wear and tear on equipment. Industries benefit from smoother operations and increased productivity. However, implementing VFD systems isn't without challenges.

Many companies face obstacles like initial costs and training staff. Sometimes, improper configuration leads to less-than-optimal results. Reflecting on these issues shows the importance of proper planning and execution. Ultimately, embracing VFD motor control can revolutionize industrial practices, but it requires thoughtful consideration and investment.

The Importance of VFDs in Energy Efficiency for Industrial Motors

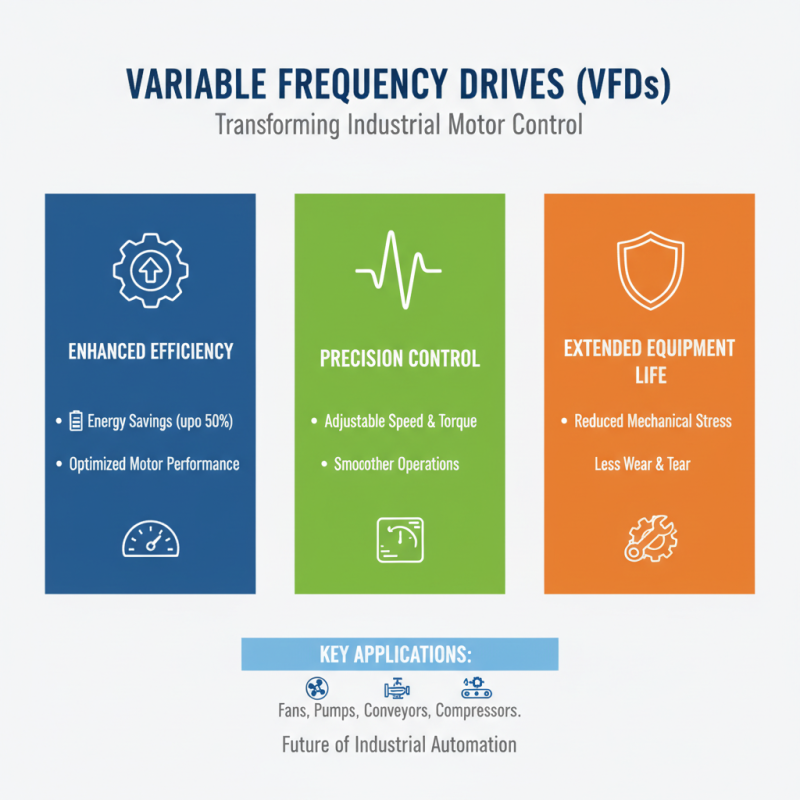

Variable Frequency Drives (VFDs) are transforming industrial motor control. They significantly enhance energy efficiency in various applications. Understanding their role is vital for modern industries.

Energy consumption in motors is often excessive. Motors usually operate at fixed speeds, wasting energy during low-demand periods. VFDs adjust motor speed based on real-time needs. This adaptation can lead to substantial energy savings. For example, a pump operating at variable loads can reduce energy use by up to 50% with proper VFD implementation.

However, not all industries utilize VFDs effectively. Some may overlook initial costs or installation challenges. Others might not fully understand how to integrate these systems. This lack of knowledge can hinder potential energy savings. Recognizing the need for training and proper integration is crucial. Ultimately, industries must confront these shortcomings to leverage the true benefits of VFDs in their operations.

Impact of VFD Motor Control on Equipment Lifespan and Maintenance Costs

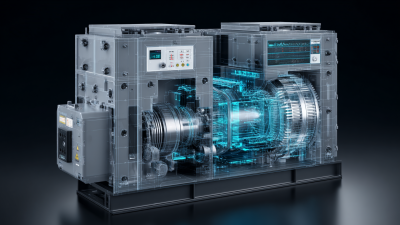

Variable Frequency Drive (VFD) motor control plays a crucial role in modern industries. It helps optimize energy usage and enhances equipment performance. A recent study indicates that implementing VFD technology can reduce energy consumption by up to 60% in various applications. This not only minimizes operational costs but also extends the lifespan of the equipment.

VFDs adjust the motor speed to match the load requirements. This adaptability leads to less wear and tear on motors, resulting in fewer maintenance issues. According to industry reports, maintenance costs can decrease by 30% when using VFDs. With reduced mechanical stress, the risk of unexpected breakdowns declines significantly.

**Tips:** Regularly monitor VFD settings to maintain efficiency. A small adjustment can have a significant impact. Ensure your personnel is trained to handle VFDs properly; human error can lead to costly mistakes. Review maintenance schedules frequently; proactive measures cost less than reactive ones.

VFD Technology: Key Features and Advantages for Modern Industries

VFD technology stands out for its efficiency in controlling motor speed and torque. VFDs can reduce energy consumption by up to 60%, according to a report from the U.S. Department of Energy. This efficiency is vital as industries seek to lower operational costs. The control of motor speeds allows factories to optimize their production processes. Machines can run only at necessary speeds, reducing wear and tear over time.

Another key feature of VFDs is their ability to provide smooth acceleration and deceleration. This minimizes mechanical stress on equipment. Abrupt starts and stops can lead to failure, costing industries time and money. In industries like water treatment, utilizing VFDs improved system reliability. A study indicated that over 30% of treatment plants adopted VFDs to enhance operational efficiency.

However, implementing VFDs requires careful consideration. Not all applications benefit from variable frequency drives. Sometimes, fixed-speed systems perform better. It's essential to analyze specific processes before deciding. In some cases, improper installation can lead to issues such as harmonic distortion. This can negatively affect other electrical equipment. Thus, while VFDs offer clear advantages, the decision-making process cannot be overlooked.

Why VFD Motor Control is Essential for Modern Industrial Applications

| Feature | Description | Advantage |

|---|---|---|

| Speed Control | Allows precise control of motor speed for various applications. | Increases efficiency and reduces energy consumption. |

| Soft Start | Gradually ramps up the motor speed to reduce mechanical stress. | Extends motor life and decreases maintenance costs. |

| Torque Control | Maintains constant torque under varying loads. | Improves performance in high-load conditions. |

| Energy Savings | Optimizes energy usage based on demand. | Significantly lowers operational costs. |

| Advanced Diagnostics | Monitors performance and detects issues in real-time. | Facilitates proactive maintenance and reduces downtime. |

Sector-Specific Applications of VFDs in Manufacturing and Beyond

Variable Frequency Drives (VFDs) are transforming modern manufacturing. In the food and beverage sector, for example, energy efficiency is critical. A report by the U.S. Department of Energy states that VFDs can reduce energy consumption by up to 50% in many applications. This is especially important as food safety and sustainability concerns rise.

In the textile industry, precise motor control is necessary. VFDs allow for adjustable speeds, enhancing product quality. The International Electrotechnical Commission found that using VFDs can increase productivity by 30% in textile plants. However, many facilities still rely on outdated methods. Upgrading systems can be daunting due to costs and training.

VFDs also help in HVAC systems. These systems can adjust airflow and cooling based on demand. A study from the American Society of Heating, Refrigerating and Air-Conditioning Engineers highlighted that energy savings can exceed 40% with VFDs. Despite the clear benefits, some engineers hesitate due to complexity. This reluctance may lead to missed opportunities.

Recent Trends and Innovations in VFD Motor Control Solutions

Variable Frequency Drives (VFDs) are transforming modern industrial applications. Recent trends highlight their growing adoption in sectors like manufacturing and HVAC. According to a report from Research and Markets, the global VFD market is projected to reach $27.8 billion by 2027, growing at a CAGR of 7.4%. This indicates a strong shift towards efficiency and flexibility.

Innovative VFD solutions integrate advanced algorithms and smart technologies. These features enhance energy savings and operational efficiency. For example, the latest VFDs can adapt to load conditions in real time. This adaptability reduces operational costs while improving system performance. However, many companies still struggle to fully embrace these advancements. Overcoming resistance to change is essential.

**Tip:** Regular training can help your team adapt to new VFD technologies. Ensuring everyone is on the same page boosts overall efficiency.

Adding IoT connectivity to VFDs is another emerging trend. This integration allows for remote monitoring and diagnostics, minimizing downtime. Industry experts estimate that predictive maintenance can save businesses up to 12% in repair costs. However, not all facilities have implemented this technology yet. This gap can lead to missed opportunities in maintaining system health.

**Tip:** Consider pilot programs for IoT-enabled VFD solutions. Testing in a controlled environment can reveal valuable insights for a wider rollout.

Related Posts

-

How to Choose the Right VFD Drive for Your Industrial Application

-

Unlocking the Power of Frequency Drives for Energy Efficient Automation Solutions

-

Top Benefits of Variable Frequency Motor Controllers for Efficient Energy Use

-

2026 Top Variable Frequency Motor Controllers What to Know?

-

Why Do You Need a Soft Starter for Your Electrical Motor System?

-

Essential Checklist for Choosing the Right Motor Starters in Global Supply Chains